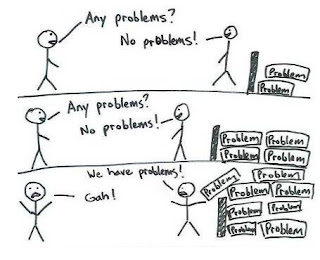

Here is an example of a causal diagram I once made to understand challenges in a complex SAP development and roll-out program, where milestones were systematically not met. The white circles describe causes and effects, where the arrows indicate how one topic has a causal relationship to another. For example, running many projects in parallel causes competition for scarce resources.

Let's have a closer look at how this works using the above example, starting at the bottom right: running many interrelated projects in parallel is increasing the complexity and dependencies in each of the projects. This increased complexity made it hard to make a reliable overall plan. Furthermore, all these projects were competing for scarce resources. When an issue or delay in a high priority project pulled for more scarce resources than planned, other projects where these people originally were planned to work on, were delayed. As a quick fix, it was as a rule agreed that critical resources would only be allocated shortly in advance and for a short period of time; in other words to allow them to work on where the biggest fires were. Consequently, since nobody knew whether critical resources would be available as planned, the quality and relevance of (short term) planning of projects was getting poorer. Basically, people were thinking: "Why bother investing time in making a serious planning; I never get the people I need for my project anyway." As a result, there was no real commitment for any of the timelines of the projects that were on the table. Also, challenging project managers on not meeting their deadlines, systematically resulted in the answer: "I'm not getting a response or availability (from the critical resources)". Gradually, the local roll-out management stopped challenging their local project managers. So, the incentive for good planning and execution slowly diminished. All in all, this resulted in a self enforcing mechanism of constant project replanning, with deteriorating quality of planning, poor commited project managers and nobody who was really following up on realisation of plans.

It took me a while to understand what was really going on. Mapping the interdependencies in a causal diagram helped in analysing the problems and finally defining the countermeasures.