zondag 27 februari 2011

dinsdag 15 februari 2011

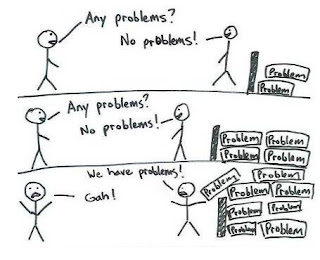

No problem is problem

I just love the following image ! It's great for discussing some lean concepts with your team: e.g. the role of the manager, the mental model of "problems are gold", the importance of visualizing problems, the importance of continuous improvement.

Here are some questions to trigger people's thinking:

Here are some possible anwers:

Source of image : unknown - pls. inform me if you know the author.

Here are some questions to trigger people's thinking:

- Why does the person on the right (R) say there is no problem ?

- Why does the person on the left (L) accept his 'No problems!' answer ?

- Assuming that (L) is the manager, what does he do right ?

- What happens after the third image ? What culture and behavior are fostered ?

Here are some possible anwers:

- The wall hides (R)'s problems; (R) cannot see his problems. Maybe (R) has learned that it is better to hide problems because e.g. the messenger usually gets shot or gets instructions on what to do about ( i.e. get more work). Maybe (R) even built that wall for that purpose ?

- (L) has no way of verifying that there no problems, as the problems are not visible.

- (L) is at the gemba and inviting (R) to talk about his problems. ( Note: Consider asking "What are your problems?" instead of "Do you have any problems?" The first questions sets the expectation that there always are problems. )

- Everybody is firefighting everywhere, everyday. Consequently, there is less and less time to prevent problems by eliminating root-causes. The prevailing mindset becomes: "our hero's are the firefighters" instead of "our hero's are the fire prevention team".

Source of image : unknown - pls. inform me if you know the author.

maandag 14 februari 2011

Lean Leadership Behaviour and Actions

Here is a simple pocket card which reminds us of lean management behaviour and actions.

Click image for quality viewing or printing.

Click image for quality viewing or printing.

Source : Lean Leadership - The Invisible Force by Thomas Thorsted & Peter Knorst

dinsdag 8 februari 2011

Why do we need continuous improvement ?

Our business processes are constantly exposed to changes in the environment. These changes impact and deteriorate the effectiveness our company's processes. I like the analogy of a spider web: constant exposure to wind and rain causes filaments to break. (1)

Without continuous improvement.

If our staff is not trained on properly addressing the changes and their impact on our processes, they may not take any action or at best create workarounds to fix the problems (instead of addressing the root causes). Over time, problems and/or workarounds accumulate with increasing complexity and decreasing overall process performance as a result. It becomes more and more likely that another 'improvement project' will be required. Back to the analogy of the spider web: if the spider fails to repair the broken filaments frequently and systematically, big wholes will emerge in the web which render the web useless and leave the spider without food.

With continuous improvement.

Now take the scenario where staff is trained in continuous improvement and supported by their manager to address these problems on a daily basis. First, problems caused by changes in the environment will surface earlier because staff has 'learned to see' problems and is supported by visual management tools (e.g. visual process adherence, visual process performance). Second, the continuous improvement mindset encourages staff to bring up problems. ( cf. mental model "problems are gold" ) Thirdly, staff will address the problems using structured problem solving ( cf. A3 Thinking ). Not only will they identify and fix root causes, but also implement improved standards and monitoring. These problem solving activities can take place during stand-up meetings, quality circles and individual coaching by supervisors. Here's how continuous improvement fits the analogy of the spider: she repairs broken filaments on a daily basis to ensure that the quality of her food collection process is maintained. Last but not least, by implementing a system of continuous improvement, the performance of processes will not just be maintained to but also improved.

A spider repairs broken filaments in her web on a daily basis to ensure the quality of her food collection process is maintained

(1) Source of this analogy: "The Remedy", Pascal Dennis

maandag 7 februari 2011

Four building blocks for driving effective change.

Here's a nice visual representation of four building blocks for driving effective change. I particularly like the description of what happens when one of the building blocks is missing.

Source: unknown

Source: unknown

vrijdag 4 februari 2011

Lean Principles as Generic Target Condition

Today I was thinking about how Womack's five lean principles ( Customer Value, Value Stream, Flow, Pull, Perfection ) fit in the overall concept of the improvement Kata as described by Mike Rother. In summary, my conclusion is that the five lean principles set a generic target condition for any improvement activity in an organisation.

Before becoming a lean thinker, I was educated in the Six Sigma school of thought. What struck me when first learning about lean was that it gave me guiding principles on how to optimize processes. These principles are Customer Value, Value Stream, Flow, Pull and Perfection (1). In my experience until then, Six Sigma had no such thing, other then a CTQ tree which designs customer expectations and CPk's (process capability) which measure the extend of meeting these expectations.(2) Clearly I'm not a master black belt, but having mentored many six sigma projects, I found that depending on the team I worked with, solutions to the same problems could be radically different. (3)

Even without fully grasping the real meaning and potential of these lean principles, they provided a lot of guidance for designing solutions. Honestly, I experienced it as a relief! Come on ... the solution chosen to be implemented could not just be determined by who was in the team (or which voting system was used) ...

Then I learned about the Improvement Kata in Mike Rother's book. Any improvement activity should start not only with a (measurable) problem statement, but also with a target condition. A target condition describes not only the measurable process indicators ( or target outcome) but also the ideal process design to give guidance to the solutions that should be developed. As I understood the importance of the target condition, I suddenly realised why an ideal state VSM was so important ...

Now let's fit the Lean Principles and the Improvement Kata together. For any (point or system) Kaizen I engage in, I will use the improvement Kata approach and design an ideal state which represents my target condition. In designing the ideal state and target condition, I will always use the Lean Principles as generic guidelines.

Imagine that all improvement activity within your organisation is using this approach ... -isn't that what the principles are meant for?-. Basically the lean principles will function as a generic target condition for any improvement activity in an organisation.

The summary of my lean learning for today: The five lean principles set a generic target condition for any improvement activity in an organisation.

-----

(1) I'm using Womack's five principles, but I could as wel refer to the 14 Toyota Way principles.

(2) I agree that by having added lean tools to the Six Sigma portfolio (turning it into Lean Six Sigma), some of guiding principles are now included.

(3) Here is an example to illustrate this. In trying to reduce lead time of refunding customers for credit notes issued, a six sigma team decided to move processing of refunds to India. This solution allowed to use a lot of cheap labor for fast refund processing, in a process with more muda which was less flexible ( due to e.g. language and distance) and not capable of communicating with front line teams or customers. The CPk objectives ( 60% lead time reduction) and required cost reduction (!) were achieved. Now, imagine what the solution would have looked like if this team would have used lean principles in designing the future state ...

Before becoming a lean thinker, I was educated in the Six Sigma school of thought. What struck me when first learning about lean was that it gave me guiding principles on how to optimize processes. These principles are Customer Value, Value Stream, Flow, Pull and Perfection (1). In my experience until then, Six Sigma had no such thing, other then a CTQ tree which designs customer expectations and CPk's (process capability) which measure the extend of meeting these expectations.(2) Clearly I'm not a master black belt, but having mentored many six sigma projects, I found that depending on the team I worked with, solutions to the same problems could be radically different. (3)

Even without fully grasping the real meaning and potential of these lean principles, they provided a lot of guidance for designing solutions. Honestly, I experienced it as a relief! Come on ... the solution chosen to be implemented could not just be determined by who was in the team (or which voting system was used) ...

Then I learned about the Improvement Kata in Mike Rother's book. Any improvement activity should start not only with a (measurable) problem statement, but also with a target condition. A target condition describes not only the measurable process indicators ( or target outcome) but also the ideal process design to give guidance to the solutions that should be developed. As I understood the importance of the target condition, I suddenly realised why an ideal state VSM was so important ...

Now let's fit the Lean Principles and the Improvement Kata together. For any (point or system) Kaizen I engage in, I will use the improvement Kata approach and design an ideal state which represents my target condition. In designing the ideal state and target condition, I will always use the Lean Principles as generic guidelines.

Imagine that all improvement activity within your organisation is using this approach ... -isn't that what the principles are meant for?-. Basically the lean principles will function as a generic target condition for any improvement activity in an organisation.

The summary of my lean learning for today: The five lean principles set a generic target condition for any improvement activity in an organisation.

-----

(1) I'm using Womack's five principles, but I could as wel refer to the 14 Toyota Way principles.

(2) I agree that by having added lean tools to the Six Sigma portfolio (turning it into Lean Six Sigma), some of guiding principles are now included.

(3) Here is an example to illustrate this. In trying to reduce lead time of refunding customers for credit notes issued, a six sigma team decided to move processing of refunds to India. This solution allowed to use a lot of cheap labor for fast refund processing, in a process with more muda which was less flexible ( due to e.g. language and distance) and not capable of communicating with front line teams or customers. The CPk objectives ( 60% lead time reduction) and required cost reduction (!) were achieved. Now, imagine what the solution would have looked like if this team would have used lean principles in designing the future state ...

donderdag 3 februari 2011

Learning the difference between goals and standards

From past experience, I know how difficult it is to set good goals. In this article I will share some of my experiences and learnings in setting goals for managing and improving processes on the gemba.

As a manager of a customer care back-office department, I set overall daily productivity goals just to challenge and push my team of agents for improvement. In fact, after an initial start-up fase, the team members set their own goals for the day and my role was to challenge these goals. We discussed actual performance compared to the goals on a daily basis during 15 minute stand-up whiteboard meetings. This PDCA approach was a good basis for discussing deviation from plan and identify issues and improvement actions. However, these goals were not based on anything really ... Honestly, I didn't know if these goals were realistic and achievable, but I just pushed for little baby improvement steps every day.

Then, I had a big insight whilst working as lean consultant for a central heating installation company. Based on an analysis of McKinsey, the suggestion was to improve productivity of individual installation mechanics to the performance of the 75th percentile. I was a bit shocked, as my thinking was "Why don't we just focus on getting the performance of the bottom half up to the performance of the median." I then realised that my approach, which really meant making the mean performance the goal for everyone, resulted in no incentive for improvement for half of the installation mechanics workforce ...

Yesterday, as I was reading through "The Lean Manager" of Michael Balle, my understanding of setting goals went yet another step further. Of course I realised that "Problems are defined as gaps between standards and actuals. And yes, "A standard is the best known performance". But what new was to me, was the true understanding that a (measurable) standard should be set "based on observation of actual work content over multiple cycles". Referring to the customer care back-office example, this would be e.g. the best observed performance in cycle time to complete the administrative steps for re-ordering and picking up incorrectly delivered products to customers. The significance of this is tremendous! First, everybody understands the goal is achievable. And second, everybody - not just the bottom half performers- in the team is challenged to improve.

Now, how realistic is it to expect people to maintain that "standard" performance in cycle time for one hour or one day straight? That's the whole point of Kaizen. We should ask ourselves: How can we reach our best cycle time every cycle? This doesn't mean that the improvement is just for individual customer care agents or mechanics to achieve. It's an objective for the entire team: agents, mechanics, supervisors and managers.

By definition we should never beat the standard. For, if it is possible to beat the standard, the standard does not represent the best known performance and we should change the standard. When we outperform the standard, we must have included waste in the definition of the standard. If we include waste in our standards, there is absolutely no incentive for the team to solve any of these problems.

Summary. A big difference between a goal and a standard is that standards are based on the best observed and measured performance. This turns a standard into a realistic and achievable goal. A standard should not include any waste and should never be outperformed, as it is intended to constantly engage everyone in improvement activities.

As a manager of a customer care back-office department, I set overall daily productivity goals just to challenge and push my team of agents for improvement. In fact, after an initial start-up fase, the team members set their own goals for the day and my role was to challenge these goals. We discussed actual performance compared to the goals on a daily basis during 15 minute stand-up whiteboard meetings. This PDCA approach was a good basis for discussing deviation from plan and identify issues and improvement actions. However, these goals were not based on anything really ... Honestly, I didn't know if these goals were realistic and achievable, but I just pushed for little baby improvement steps every day.

Then, I had a big insight whilst working as lean consultant for a central heating installation company. Based on an analysis of McKinsey, the suggestion was to improve productivity of individual installation mechanics to the performance of the 75th percentile. I was a bit shocked, as my thinking was "Why don't we just focus on getting the performance of the bottom half up to the performance of the median." I then realised that my approach, which really meant making the mean performance the goal for everyone, resulted in no incentive for improvement for half of the installation mechanics workforce ...

Yesterday, as I was reading through "The Lean Manager" of Michael Balle, my understanding of setting goals went yet another step further. Of course I realised that "Problems are defined as gaps between standards and actuals. And yes, "A standard is the best known performance". But what new was to me, was the true understanding that a (measurable) standard should be set "based on observation of actual work content over multiple cycles". Referring to the customer care back-office example, this would be e.g. the best observed performance in cycle time to complete the administrative steps for re-ordering and picking up incorrectly delivered products to customers. The significance of this is tremendous! First, everybody understands the goal is achievable. And second, everybody - not just the bottom half performers- in the team is challenged to improve.

Now, how realistic is it to expect people to maintain that "standard" performance in cycle time for one hour or one day straight? That's the whole point of Kaizen. We should ask ourselves: How can we reach our best cycle time every cycle? This doesn't mean that the improvement is just for individual customer care agents or mechanics to achieve. It's an objective for the entire team: agents, mechanics, supervisors and managers.

By definition we should never beat the standard. For, if it is possible to beat the standard, the standard does not represent the best known performance and we should change the standard. When we outperform the standard, we must have included waste in the definition of the standard. If we include waste in our standards, there is absolutely no incentive for the team to solve any of these problems.

Summary. A big difference between a goal and a standard is that standards are based on the best observed and measured performance. This turns a standard into a realistic and achievable goal. A standard should not include any waste and should never be outperformed, as it is intended to constantly engage everyone in improvement activities.

Abonneren op:

Posts (Atom)